The Challenge: Quality Control at Scale

In manufacturing, quality is everything. A single defective batch can trigger recalls, customer dissatisfaction, and financial losses. Traditional quality control relies on manual inspection—a process that is:

- Slow and inconsistent.

- Vulnerable to human error and fatigue.

- Costly when scaled across multiple lines and shifts.

As industries move toward zero-defect manufacturing, leaders are asking: How can we make quality control faster, more accurate, and more reliable—without increasing costs?

Why Computer Vision for Quality Control?

Computer vision, powered by AI, has emerged as the game-changer for modern factories:

- High Accuracy: Detects even micro-defects invisible to the human eye.

- Scalability: Works 24/7, across multiple lines, without fatigue.

- Traceability: Every inspection can be logged and audited.

- Cost Efficiency: Reduces rework, warranty claims, and waste.

- Privacy & Compliance: Can run on-device, without exposing factory data to the cloud.

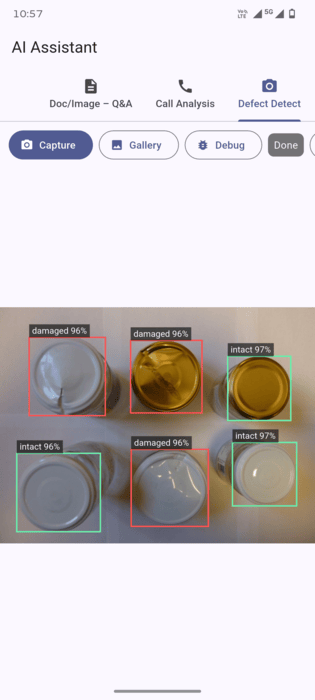

How We Solved It: SharkAI’s Mobile Defect Detection System

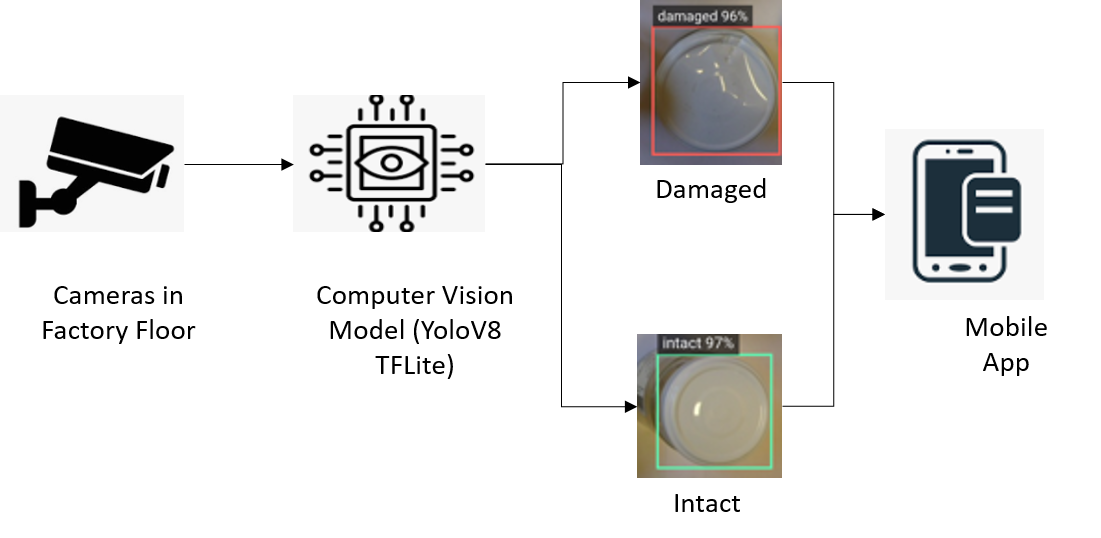

At SharkAI Solutions, we developed a mobile, on-device quality control system designed for factory-floor operators.

Business Goal

Enable fast, offline inspection of jar lids (intact vs. damaged) using a simple mobile app tab built with Flutter.

Key Capabilities

- Offline AI: Runs fully on-device (no internet required).

- Real-Time Feedback: Detects intact/damaged lids instantly.

- Operator Friendly: Simple capture → detect → decision workflow.

- Scalable Deployment: Works on commodity Android devices for easy rollout across plants.

Implementation Snapshot (Our Proven Approach)

We combined computer vision best practices with edge AI engineering to make this solution robust.

1. Data Setup

- Images of jar lids with bounding boxes labeled as intact/damaged.

- Converted Excel annotations into YOLO training labels.

2. Model Training

- Trained a YOLOv8 detection model on intact/damaged lids.

- Exported to TensorFlow Lite (TFLite) for mobile optimization.

3. Mobile App Integration

- Added a Defect Detection tab in Flutter.

- Used TFLite + Camera for real-time detection.

- Results shown with bounding boxes and confidence scores.

4. Debugging & Hardening

- Ensured preprocessing consistency.

- Resolved inference mismatches between training and TFLite conversion.

- Optimized performance for multiple device types.

Business Impact for Manufacturing Leaders

This solution demonstrates what AI-driven QC can achieve:

- 80% faster inspections compared to manual checks.

- Improved accuracy, reducing defective shipments.

- Consistent quality standards across shifts and plants.

- Lower costs, by catching issues earlier in the process.

- Scalable deployment, from one line to global facilities.

The Future of AI in Quality Control

This jar-lid pilot is just the start. The same approach can be extended to:

- Surface defects: scratches, dents, discoloration.

- Assembly verification: missing parts, misalignments.

- Packaging inspection: seal integrity, label accuracy.

- End-of-line audits: complete pass/fail reports with traceability.

By combining Computer Vision + Edge AI + Mobile-first UX, manufacturers can future-proof their quality control.

Read our related blogs https://www.sharkaisolutions.com/blog/unlocking_data_insights_ai and https://www.sharkaisolutions.com/blog/shark_blog

Partner with SharkAI Solutions

At SharkAI Solutions, we don’t just build models—we build end-to-end quality control systems that fit your production environment. From proof-of-concept pilots to full-scale rollout, we bring:

- AI model expertise (YOLO, Detectron, custom architectures).

- Edge deployments (TFLite, ONNX, Nvidia Jetson).

- Factory integration (MES/ERP, QC dashboards).

📌 Contact us to transform your quality control into a competitive advantage.