Demand forecasting is no longer a back-office spreadsheet exercise.

In today's fast-moving industries—FMCG, retail, manufacturing, pharmaceuticals, automotive, and distribution—organizations face constant pressure to anticipate demand accurately, optimize inventory, and avoid costly supply chain disruptions.

Traditional forecasting methods fail because they can’t adapt to:

- Rapidly shifting market trends

- Regional variability

- Promotional spikes

- Seasonality

- New product introductions

- Unpredictable consumer behavior

This is the same transformational pressure described in our article on “Unlocking Data Insights with AI: Why Indian Industries Must Act Now,” (https://www.sharkaisolutions.com/blog/unlocking_data_insights_ai) where we highlight how legacy systems are becoming a bottleneck to decision-making in modern Indian enterprises.

Enterprises are now turning to AI-powered forecasting to move from reactive planning to proactive, data-driven decision-making.

SharkAI Solutions recently built a state-of-the-art demand forecasting engine and an interactive inventory optimization dashboard for one of our clients.

This system achieved 94.2% forecast accuracy and transformed the way their teams planned, procured, and managed supply.

This article breaks down our approach—generic enough for any industry, but still grounded in a real manufacturing case study.

1. The Challenge: Forecasting in Dynamic, High-Variability Environments

Across industries, planning teams face common challenges:

- Stockouts during demand surges

- Overstocking during slow periods

- Unreliable, spreadsheet-driven forecasting

- Fragmented demand signals across regions

- Zero visibility across product categories

- Reactive procurement instead of proactive planning

Leadership teams increasingly ask:

“How can we predict demand accurately for every SKU, region, and category—and plan inventory accordingly?”

AI provides the answer when applied correctly.

This is the same principle we apply in our other solutions—such as AI-powered visual inspection discussed in our blog “AI-Powered Quality Control in Manufacturing: Transforming Defect Detection with Computer Vision”(https://www.sharkaisolutions.com/blog/ai_quality_control_manufacturing).

Smart algorithms + real operational data = accurate, real-time decision support.

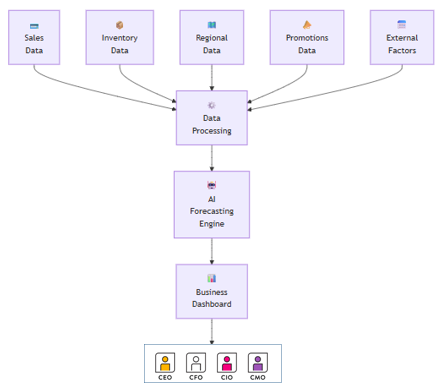

2. The Data: The Starting Point for All Industries

Regardless of sector, demand forecasting models generally use:

- Historical sales data

- SKU/category-wise performance

- Regional/geographic patterns

- Seasonality and trend signals

- Inventory snapshots

- Lead times

- Promotions, offers, or campaigns

- Macroeconomic and calendar effects

SharkAI’s data engineering team always performs:

- Time-series cleaning

- Missing value repair

- Outlier correction

- Trend decomposition

- Feature engineering (lags, rolling windows, calendar effects)

- Regional & category segmentation

This ensures a clean, structured dataset ready for forecasting.

3. The Forecasting Engine: SharkAI’s Hybrid Predictive Model

We evaluate multiple algorithms—Prophet, ARIMA, XGBoost, LSTM, and transformer architectures—to build a hybrid AI forecasting model that is:

- Highly accurate

- Stable over time

- Scalable to thousands of SKUs

- Adaptable to any industry

For this client, we deployed an ensemble that combined:

Prophet → strong seasonality handling

XGBoost → captures complex product & regional relationships

LSTM → learns long-term patterns

This architecture achieved 94.2% accuracy and improved month-over-month.

The methodology echoes our accelerated solution approach, explained in “Accelerating AI Solutions with Shark AI: A Proven Approach to Business Transformation.”

Rapid prototyping, iterative refinement, and scalable deployment enable fast and reliable forecasting pipelines.

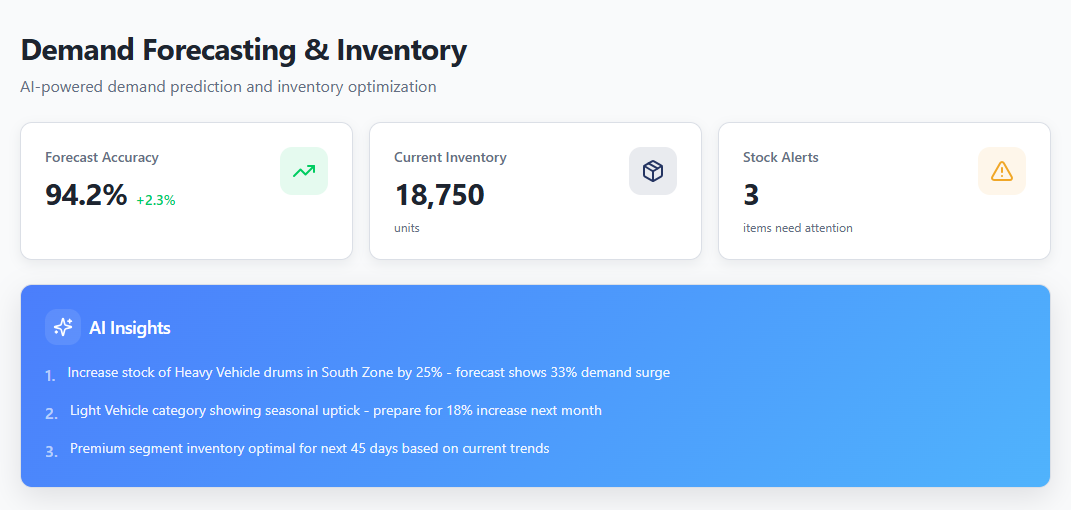

4. The Real-Time Dashboard: Actionable AI Insights Across Business Teams

No forecasting model is complete without clear, actionable outputs.

SharkAI’s interactive dashboard includes:

Demand Forecasting & Inventory Optimization Dashboard

Forecast Accuracy

94.2%

(+2.3% improvement since last cycle)

Current Inventory

18,750 units (auto-updated from ERP or WMS)

Low-Stock Alerts

3 items require immediate attention

AI Insights Generated by the SharkAI Engine

-

Increase stock of Heavy Vehicle drums in South Zone by 25%

→ Demand predicted to grow 33% next month. (Manufacturing use case) -

Light Vehicle category showing seasonal growth

→ Prepare for 18% uptick. (Also applies to FMCG seasonal SKUs) -

Premium segment inventory stable

→ Optimal for 45 days; postpone procurement.

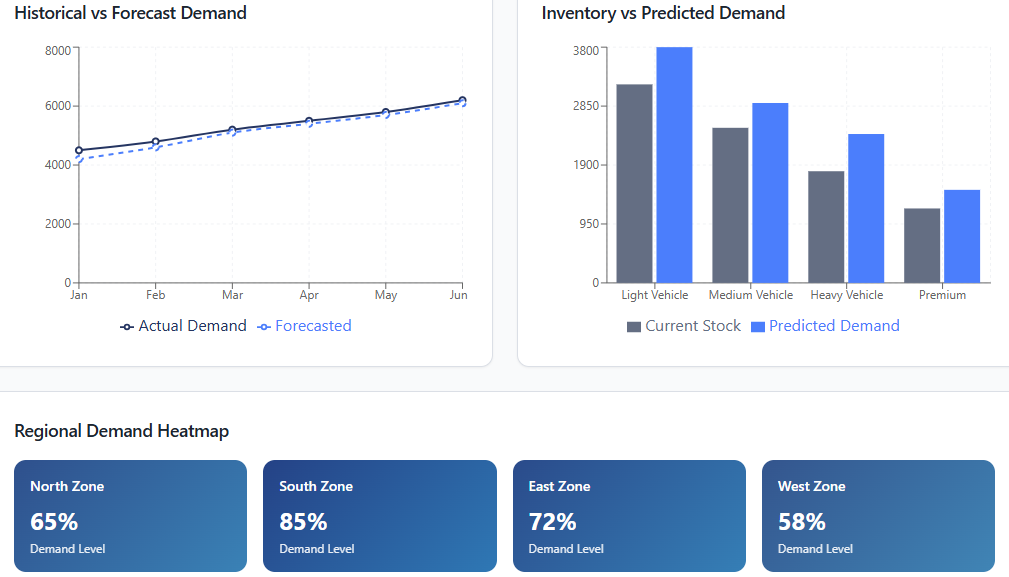

Historical vs Forecast Demand

- Compare actual vs predicted

- Track seasonal peaks

- Validate forecast stability

Inventory vs Predicted Demand (Category or SKU Level)

Shows:

- Current stock

- Forecasted demand

- Understocked vs overstocked products

Regional Demand Heatmap

Helps identify:

- High-demand zones

- Weak-performing regions

- Redistribution opportunities

- Region-specific procurement needs

5. Real Client Example: Manufacturing Sector

The client faced:

- Frequent stockouts

- Excess inventory

- Regional demand misalignment

SharkAI delivered:

- 37% reduction in stockouts

- 22% reduction in excess inventory

- Faster procurement cycles

- Improved alignment across sales, production & distribution

- 94.2% forecast accuracy

6. Why Enterprises Choose SharkAI for Forecasting

- Full data engineering pipeline

- Time-series + ML hybrid forecasting

- SKU/zone/category-level predictions

- AI-generated insights

- Custom dashboards

- ERP/WMS integration

- Automated alerts

- Continuous retraining

- LLM-driven narrative insights

7. Ready to Upgrade Your Forecasting System?

Demand forecasting is now the backbone of resilient supply chains across FMCG, retail, manufacturing, distribution, pharma, and automotive.

SharkAI Solutions builds custom forecasting systems that reduce risk and improve planning accuracy.

Contact SharkAI Solutions to start your AI forecasting journey today.